recommend products

The company's main caliber DN50 ~ DN4000, pressure 0.25 ~ 6.4MPa soft, hard, one-way, two-way sealing butterfly valve, eccentric half ball valve, flow regulating valve, pipeline expansion device force transmission joint and other fluid control equipment

Zhengzhou Top Valve

A collection of scientific research, industry and trade, service in one of the high-tech enterprises

Zhengzhou Top Valve Fluid Technology Co., Ltd.is a high-tech enterprise integrating scientific research, industry and trade, and service. The company is located in the valve industrial park of Gaoshan Town, Xingyang City, Zhengzhou City, Henan Province, covering an area of more than 30000 square meters. The company implements CAD research and development design and three-dimensional simulation auxiliary test; established ERP digital information of financial e-commerce, manufacturing, sales and service functions and enterprise information management system of Zheng Yi technology network.

The company's main caliber DN50 ~ DN4000, pressure 0.25 ~ 6.4MPa soft, hard, one-way, two-way sealing butterfly valve, eccentric half ball valve, flow and pressure regulating valve, pipe telescopic force transmission joints and other fluid control equipment. Products are widely used in urban water supply and drainage, heat, fire, petroleum, chemical, marine engineering, rail transit, metallurgy, electric power, water conservancy, construction, mining and other fields. The market covers the whole country and is exported to North and South America, Europe, the Middle East and Southeast Asia.

Company established in (year)

Floor Area (㎡)

Existing Employees (person)

Total investment (billion)

Quality Assurance

Intelligent Manufacturing · Become a Fluid Control Service Operator

Technical research

Fine and rigorous management ensures the production of high-quality products, with the primary task of researching and producing high-quality products and providing satisfactory services to customers. Quality is regarded as life,

Production equipment

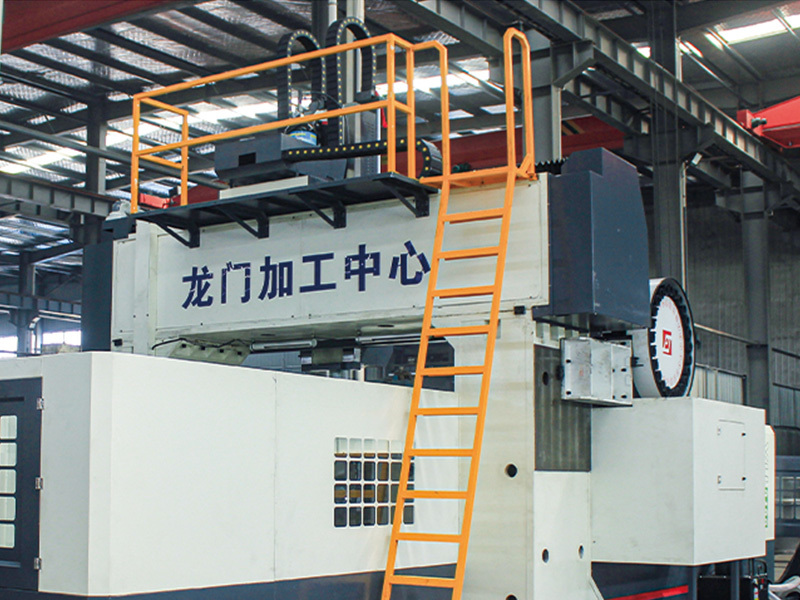

The large vertical lathes, boring machines, CNC machining centers and other equipment in the production workshop have been installed and are currently in operation.

Testing Center

Zhengzhou Top Valve has established a 3S management standard for "raw material testing, process testing, and finished product testing". Strictly follow the IS09001 quality management system standard for quality management control.

Production Equipment

The company has excellent machinery and equipment, with various types of machining, welding and testing equipment more than 300 sets. CNC lathe, CNC vertical lathe, gantry machining center, automatic sealing surface surfacing robot, electrostatic powder spraying production line and other equipment, as well as advanced sealing performance testing equipment, physical and chemical testing center, are in the leading level of the industry.

News

23

05

2024

High temperature and high pressure check valve maintenance ten measures introduced

Lubricate with grease. Grease should be compatible with high temperature and high pressure valve metal materials, rubber parts, plastic parts and working medium. When the working medium is gas, special 221 grease, for example, can be used. Apply grease to the surface of the seal installation groove, apply grease to the rubber seal, and apply grease to the sealing surface and friction surface of the valve stem.

→